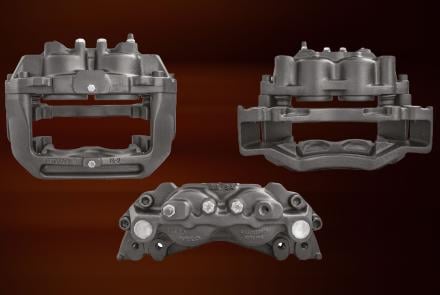

Majorsell Compressori per aerofreni

Alla fondazione di MajorsellL'eccellente offerta di prodotti di è costituita dalla nostra vasta gamma di compressori per freni ad aria compressa per camion, autobus e veicoli fuoristrada, che copre la maggior parte dei principali produttori di freni come Wabco, Knorr Bremse e Haldex.

I clienti possono specificare entrambi una nuova unità OE sostitutiva, una qualità eccellente Majorsell assemblaggio nuovo di zecca or un compressore rigenerato prodotto nel nostro impianto di ingegneria in loco di prima classe, approvato secondo gli standard ISO 9001 e 14001 Majorsell I compressori di marca sono completamente rigenerati utilizzando un processo che incorpora molti anni di ricerca e sviluppo, consentendo ai nostri tecnici di produrre costantemente unità ricostruite con prestazioni e durata di servizio che soddisfano o superano l'OE.

Compressori Bendix Compressori Clayton Compressori Cummins Compressori Knorr Bremse MAN Compressori Compressori Wabco