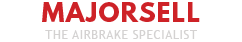

Majorsell Reman Compressors: Sustainability and Value

In today's industrial landscape, sustainability is not just a buzzword; it's a vital consideration for businesses aiming to reduce their environmental footprint while optimizing their operations. One avenue through which companies can achieve this dual objective is by opting for remanufactured compressors over new compressors. Remanufactured compressors offer a host of benefits, ranging from cost savings to environmental conservation, making them a compelling choice for forward-thinking organizations.

Sustainability at Its Core

Remanufacturing is a process that involves restoring used products to like-new condition, thereby extending their lifespan and diverting them from landfills. By choosing remanufactured compressors, businesses contribute to the circular economy, where products are reused, refurbished, or recycled rather than discarded after a single use. This approach minimizes the demand for raw materials and energy-intensive manufacturing processes associated with producing new compressors, thereby lowering carbon emissions and preserving natural resources.

Cost-Effectiveness Without Compromise

One of the primary concerns for businesses is the bottom line. Remanufactured compressors offer a cost-effective alternative to purchasing new equipment without sacrificing quality or performance. While the initial investment may be lower compared to buying brand-new compressors, the value derived from remanufactured units is significant.

Remanufactured compressors undergo rigorous refurbishment processes, including disassembly, cleaning, inspection, replacement of worn or damaged parts, reassembly, and testing. These processes ensure that the remanufactured compressor meets or exceeds the performance standards of its new counterpart. Additionally, Majorsell remanufactured compressors come an extensive warranty, providing peace of mind to businesses regarding their reliability and longevity.

Environmental Responsibility

In a world grappling with climate change and resource depletion, businesses have a responsibility to adopt sustainable practices. Choosing remanufactured compressors aligns with this ethos by reducing the environmental impact associated with equipment procurement and disposal.

The remanufacturing process consumes fewer resources and generates less waste compared to manufacturing new compressors from scratch. Moreover, by extending the lifespan of existing equipment, remanufacturing reduces the demand for new raw materials, energy, and transportation associated with producing and distributing new compressors. This translates into tangible environmental benefits, including reduced greenhouse gas emissions and conservation of natural habitats.

In conclusion, the decision to choose remanufactured compressors offers a win-win scenario for businesses seeking sustainability and value. By opting for remanufactured units, companies can reduce their environmental footprint, lower operational costs, and uphold their commitment to responsible business practices.

In an era where environmental stewardship and economic efficiency are paramount, remanufactured compressors emerge as a compelling choice for businesses across various industries. By embracing this sustainable solution, companies can not only optimize their operations but also contribute to a healthier planet for future generations.

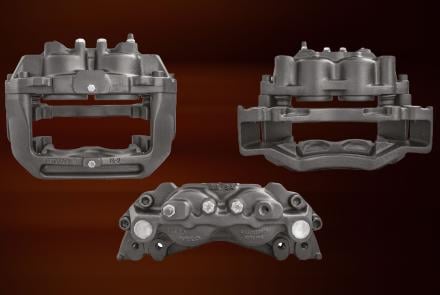

Why choose Majorsell?

Majorsell is an Air Brake Specialist who have been remanufacturing compressors for over 40 years. Our reman compressors are rebuilt in our first-class on-site engineering facility approved to ISO 9001 and 14001 standards. We believe that the care and expertise built in to every one of our remanufactured compressors sets their quality high above that of many of our competitors’ products. Every remanufactured compressor also comes complete with an extensive warranty.

View our full range of compressors: www.majorsell.co.uk/compressors